Features

- Chop-Check Lower End Style

- 43:1 Ratio

- 4 1/4'' Air Motor

- 0.74 GPM (2.8 LPM) max flow

- Capable of moving medium to high viscosity fluids ranging from 15,000 to more than 1,000,000

Pump Casing Materials

- Lower Pump Material - 300 Series Stainless Steel

- Lower Pump Material - Carbon Steel, Nickel-Plated

Packing Options

- AF0443T21GN47 17-4 Stainless Steel w/Hard Chrome Plunger - UHMW-PE/Glass Filled PTFE (Staggered) / UHMW-PE, Hydraulic Gland Type - Lower end 67101-P43

- AF0443T21GF47 17-4 Stainless Steel w/Hard Chrome Plunger - UHMW-PE/Glass Filled PTFE (Staggered) / UHMW-PE - Lower end 67101-P48

- AF0443S21GN47 Carbon Steel Plunger - UHMW-PE/Glass Filled PTFE (Staggered) / UHMW-PE, Hydraulic Gland Type - Lower end 67100-P43

- AF0443S21GF47 Carbon Steel Plunger - UHMW-PE/Glass Filled PTFE (Staggered) / UHMW-PE - Lower end 67100-P48

- AF0443S71GN47 Carbon Steel Plunger - UHMW-PE/Glass Filled PTFE (Staggered) / UHMW-PE, Hydraulic Gland Type - Lower end 67100-P43

Accessories

- 67445-1 Muffler Kit

- 66334-B Wet-Sol Packing Lubricant

- 23644-400 ARO-Stop Valve

- 67136 Floor/Mount Plate Adapter

- 67442 Ball Valve Regulator

- 637489 Universal Air Motor Service Kit

Repair Kits

- 637291-P43 637291-P48 637290-P43 637290-P48

| RATIO | 43:1 |

|---|---|

| Stroke | 4” (10.2 cm) |

| Material Inlet | Follower Plate Mounted |

| Material Outlet | 1/2” NPT(F) |

| Air Inlet (female) | 1/2” NPT(F) |

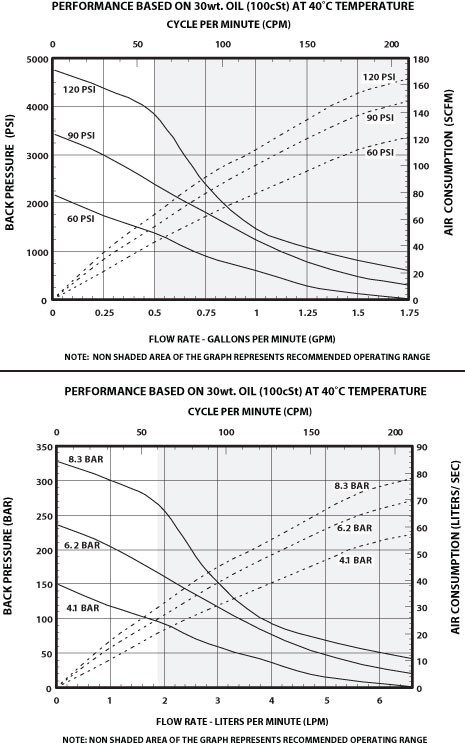

| Air Inlet Pressure Range psi (bar) | 0 - 150 (0 - 10.3) |

| Fluid Pressure Range psi (bar) | 0 - 6549 (0 - 451.7) |

| Max Cycles/Minute | 60.0 |

| Displacement/Cycle cu in (cm3) | 2.8 (45.8) |

| Cycles/gal (L) | 81 (21.7) |

| Flow @ 60 Cycles gpm (L/min) | 0.74 (2.8) |

| Noise Level @ 60 psi dBA | 86.5 |

| Weight* lb (kg) | 44 (20) |

| Container Suitability | 5 Gallon (35 lbs) |

?

?

?

?

Dimensions

| STANDARD | EXT. TIE RODS | |

|---|---|---|

| A 1 in (mm) | 42.09 (1069.09) | 50.99 (1295.15) |

| B in (mm) | 24.44 (620.83) | 33.34 (846.89) |

| C in (mm) | 14.19 (360.48) | 14.19 (360.48) |

*For models without ball valve regulator subtract 2.08 in (52.83 mm)

ENGINEERING OPERATION & MAINTENANCE MANUAL