ARO's Shock Blocker Pulsation Dampers are perfect for process applications where material foaming, hydraulic shock or material splashing are an issue. In high backpressure applications, ARO's dampeners can reduce pulsations by 60% to 80%. Shock Blocker's stainless steel bolted construction will provide a leak-free vessel and overall safer work-site. The rugged construction both inside and out will deliver worry-free, near pulse-free fluid handling performance.

Diaphragm pumps of any type have at least two points in their cycle where they provide no pressure or flow to a process. The unwanted result of this pressure fluctuation can often be material foaming, material pulsation, hydraulic shock or material splashing. While traditional pulsation dampeners can help reduce unwanted pulsation and other problems, they also require operator intervention and adjustments.

Features

- Automatic Air Adjustment - compensates for fluctuations in fluid pressure without operator intervention

- Significant Pulsation Reduction - Shock blockers deliver an average 60 - 80% pulsation reduction in high back pressure applications

- Built for High-Flow / Aggressive Fluid Applications - the 2" models can handle up to 159 cubic inch maximum fluid volume, and 3" models up to 509 cubic inch maximum fluid volume

- Broad Material Range for Compatibility - choose from PVDF, polypropylene, groundable acetal (1" models) or aluminum, cast iron or stainless steel (2" and 3" models) body materials for optimum pump-to-pulsation dampener compatibility

- Broad Diaphragm / Bladder Fluid Compatibility - choose from Santoprene, Nitrile, PTFE, Hytrel, Viton or Urethane for optimum fluid-to-diaphragm compatibility

- Perfect for Process Applications - pulsation reduction in long piping runs help prevent costly fluid pipe and downstream valve damage

- Bolted Construction - for leak-free vessel integrity and a safer work-site

- Ultra-Rugged Construction for Long Service Life - both inside and out, the new Shock Blockers are built tough to deliver worry-free, near pulse-free fluid handling

Models

- SB10X-X-X 1/2", 3/4" & 1" Pumps

- SB20X-X-X 1½" & 2" Pumps

- SB30X-X-X 3" Pumps

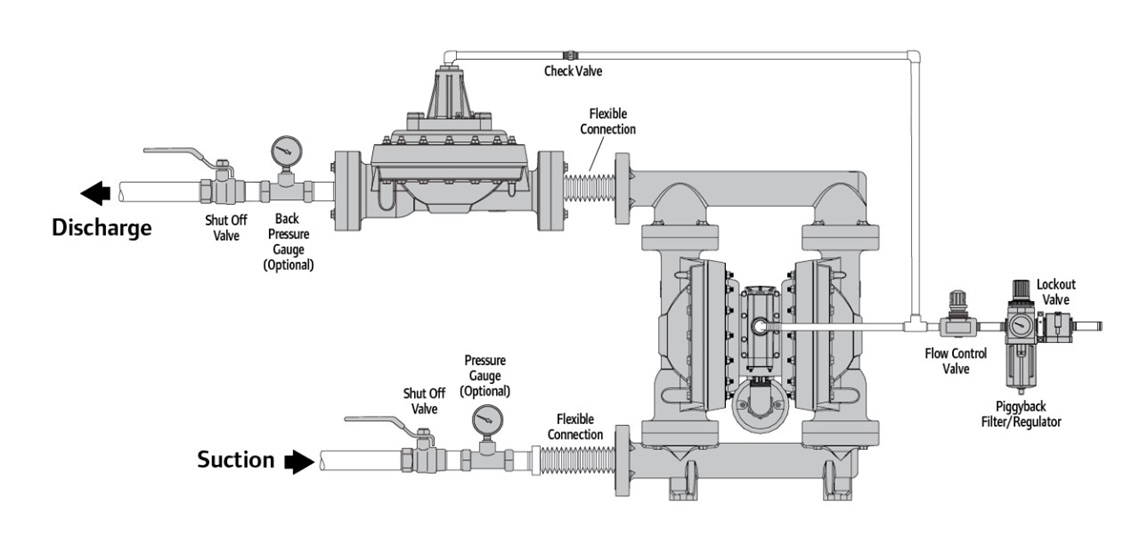

Typical Pulsation Dampener Installation

Model Series: SB20P-XXX-X, SB20R-XXX-X

Pulsation Dampener Type: Non-Metallic

Material Inlet / Outlet

- SB20P-AXX-X: 2-11-1/2 NPTF-1

- SB20P-BXX-X: Rp 2 (2-11 BSP parallel)

- SB20P-FPS-X: 2” ANSI / DIN Flange Inlet and Outlet

- SB20P-KPS-X: 2” ANSI / DIN Flange Fluid Inlet / NPTF Fluid Outlet

- SB20P-LPS-X: 2” ANSI / DIN Flange Fluid Inlet /BSPP Fluid Outlet

Air Inlet (female): 3/4 -14 NPT

Air Exhaust (female): 1/8 - 27 NPT

Weight

- SB20P-AXX-X: 41 lbs (18.6 kgs)

- SB20P-BXX-X: 41 lbs (18.6 kgs)

- SB20P-FXX-X: 45 lbs (20.4 kgs)

- SB20P-KXX-X: 43 lbs (19.5 kgs)

- SB20P-LXX-X: 43 lbs (19.5 kgs)

[add 9 lbs SB20R-XXX-X configuration with stainless steel valve body]

Pulsation Dampener Service Kit: 637550-X

Maximum Air Inlet Pressure: 120 psig (8.3 bar)

Maximum Material Inlet Pressure: 120 psig (8.3 bar)

Maximum Temperature Limits (diaphragm / seat material)

- E.P.R. / EPDM: -60° to 280° F (-51° to 138° C)

- Nitrile: 10° to 180° F (-12° to 82° C)

- Santoprene®: -40° to 225° F (-40° to 107° C)

- PTFE: 40° to 225° F (4° to 107° C)

- Viton®: -40° to 350° F (-40° to 177° C)

Maximum Fluid Volume

- SB20P-APS-X: 184 in.³ (3.02 lit.)

- SB20P-BPS-X: 184 in.³ (3.02 lit.)

- SB20P-FPS-X: 226 in.³ (3.70 lit.)

- SB20P-KPS-X: 206 in.³ (3.38 lit.)

- SB20P-LPS-X: 206 in.³ (3.38 lit.)

[Volumes same for SB20R-XXX-X configuration]